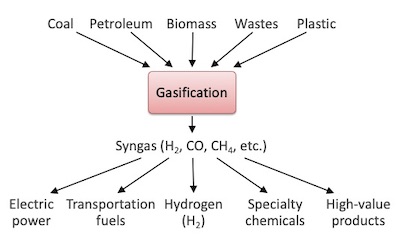

Gasification

Gasification involves converting a feedstock such as coal or biomass into a “synthesis gas” (syngas) comprising primarily hydrogen (H2) and carbon monoxide (CO), with smaller concentrations of methane (CH4) and carbon dioxide (CO2). Syngas is an extremely flexible product that can not only be burned for heat, but can be combusted in a gas turbine for very efficient electricity generation, catalytically converted to chemicals or transportation fuels, or “shifted” to produce just hydrogen and CO2, which can be separated into individual product streams.

There are two primary methods of gasification. Partial oxidation involves reacting a fuel with just 30-40% of the oxygen required for full combustion. Sufficient heat to drive the gasification reactions is generated, but instead of carbon burning completely to CO2, it reacts to form mostly CO. Similarly, hydrogen is not completely converted to H2O, but remains unoxidized as H2. The other method is steam reforming (steam gasification), in which steam reacts with carbon to form carbon monoxide and hydrogen (C + H2O → CO + H2).

Gasification reactors are classified into three general categories. In entrained-flow gasification, fuel and pure oxygen (or sometimes air) are co-fed through a burner that partially oxidizes the fuel to syngas. Entrained-flow systems are very common for gasification of coal and typically operate at very high pressures. Fluidized bed gasification involves blowing steam and/or air upwards through a hot bed of sand-like particles at high enough velocity to mix the particles around, and then introducing fuel into the reactor. There are many variants of fluidized bed reactors, which are particularly suitable for coarse feedstocks such as forest and agricultural waste. In fixed bed gasifiers, air is blown through a bed of fuel, which is heated and undergoes partial oxidation to form syngas. The U.S. Department of Energy National Energy Technology Laboratory has an excellent description of gasification technologies.

Research in the Whitty Laboratory

Our research spans a wide range of scales, from investigating fundamental reaction kinetics of tiny 10mg samples of fuels to measuring syngas and slag properties in our 1 ton/day pressurized, oxygen-blown, entrained-flow gasification pilot plant. We study partial oxidation and steam reforming, as well as CO2 gasification and hydrogasification. We have several entrained-flow and fluidized bed reactors to study just about any feedstock. Over the years we have gasified coal, petroleum coke, petroleum oils, glycerin, biomass, municipal solid waste and black liquor. Our labs are exceptionally well equipped for studying gasification, especially high-pressure processes. We especially enjoy tackling new fuels and studying new technologies. We work with collaborators on syngas cleanup, catalytic synthesis processes and air separation.

1 ton/day pressurized, oxygen-blown, entrained-flow gasification pilot plant.

High pressure thermogravimetric analyzer (HPTGA) for study of reaction kinetics.